MEMBRANE WATER PROOFING SYSTEM

MEMBRANE WATERPROOFING SYSTEM

Bituminous products are perfect for the waterproofing of roofs on buildings as they move with the structure as they are not too rigid and do not absorb water. Waterproofing membranes systems are designed to protect both residential and commercial buildings through a mixed substance made up of organic liquids that are highly sticky and viscous. Also can be used as a continuous waterproofing membrane for foundations, basements, tunnels, concrete etc. and it is applied by flame bonding.

Bituminous membranes are made up of more than one product.Bitumen -mixed with a filler (limestone or sand) component such as sand. Polymers are added to the bitumen such as APP (atactic polypropylene) a plastic additive that gives rigidity and tear resistance, or SBS (styrene butadiene styrene a rubber additive that gives more elastic benefits.

Base Products

Polyester, fiberglass, rag fiber (hessian), and paper. These products are bought in roll format and are pulled through the bitumen mixes on huge rollers. The base product becomes saturated in huge tanks by the tar-like bitumen substance, creating rolls of waterproof material.

Advantages of this system

- Uniform thickness

- Membrane can be polyester re-enforced ensuring dimensional stability.

- Excellent stability at high & low temperatures applications & service

- Higher tear & impact resistance & excellent

- Available in plain or mineral finish for light foot traffic.

- Elasticity even at low temperatures than other membranes.

Surface Preparation:-

The surface on which the membrane is to be applied must be sound, clean, and dry. Dust loose materials, protrusion must be removed cracks, holes, etc must be covered.

Priming:-

Apply Polycot primer at a coverage rate of 1-4 m2 / lt. /coat through the help of Brush / Roller

Alignment:-

Unroll and align membrane rolls and re-rolling correctly keeping an overlap as

150 mm side laps

200 mm end laps

Membrane Application:-

Torching- Position the rolls with the correct orientation, heat the lower surface of the rolls with a propane gas torch, and unroll as the bitumen begins to melt, Roll forward and press firmly with a roller against the substrate to bond

Sealing- The membrane is needed to seal properly; heat both the overlaps and use the round-tipped trowel to seal the overlap

Upstands– All angles and abutments should be sealed with extra care to ensure full bonding, sealing the edges well into the grooves or protective auxiliary materials

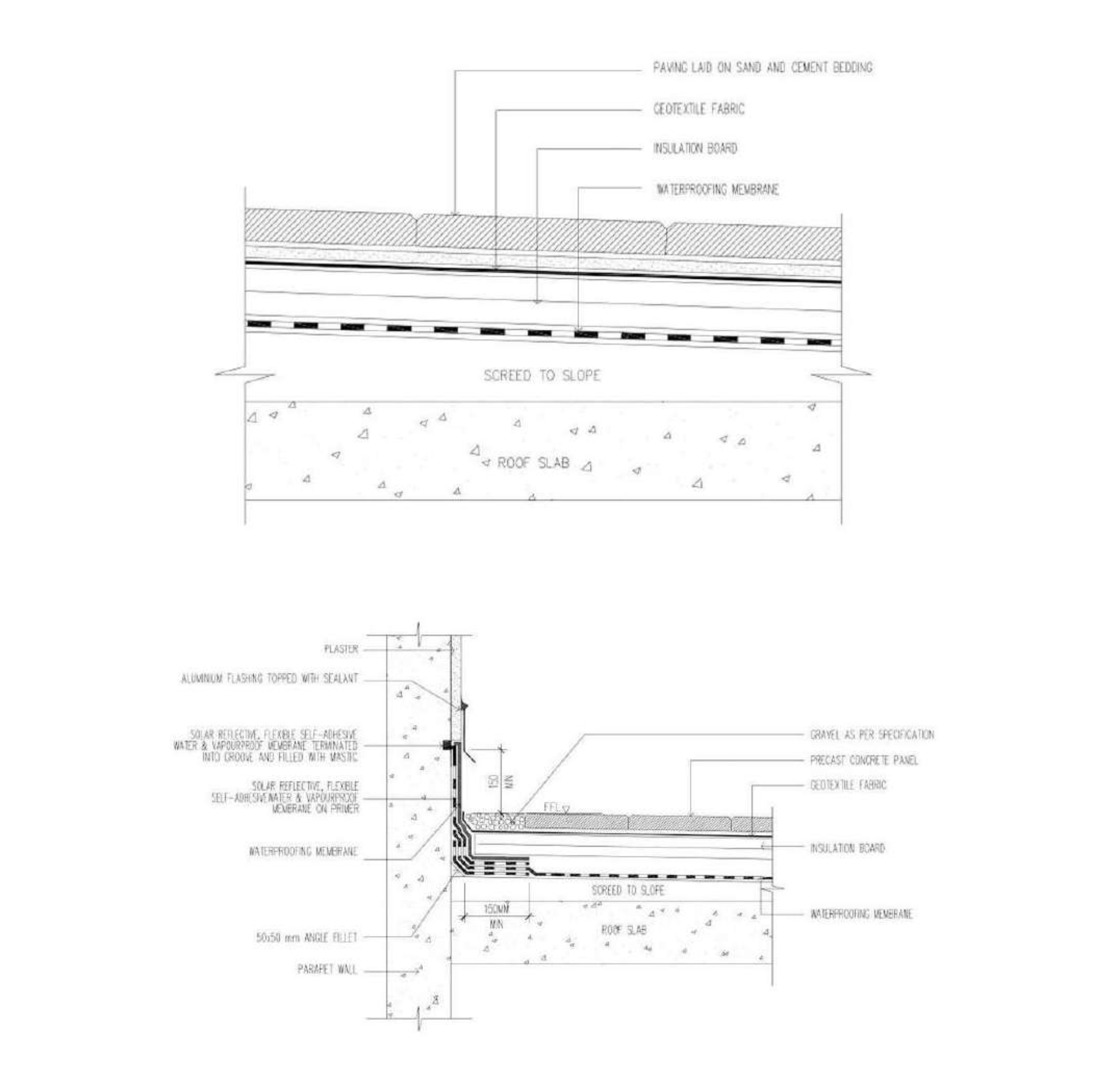

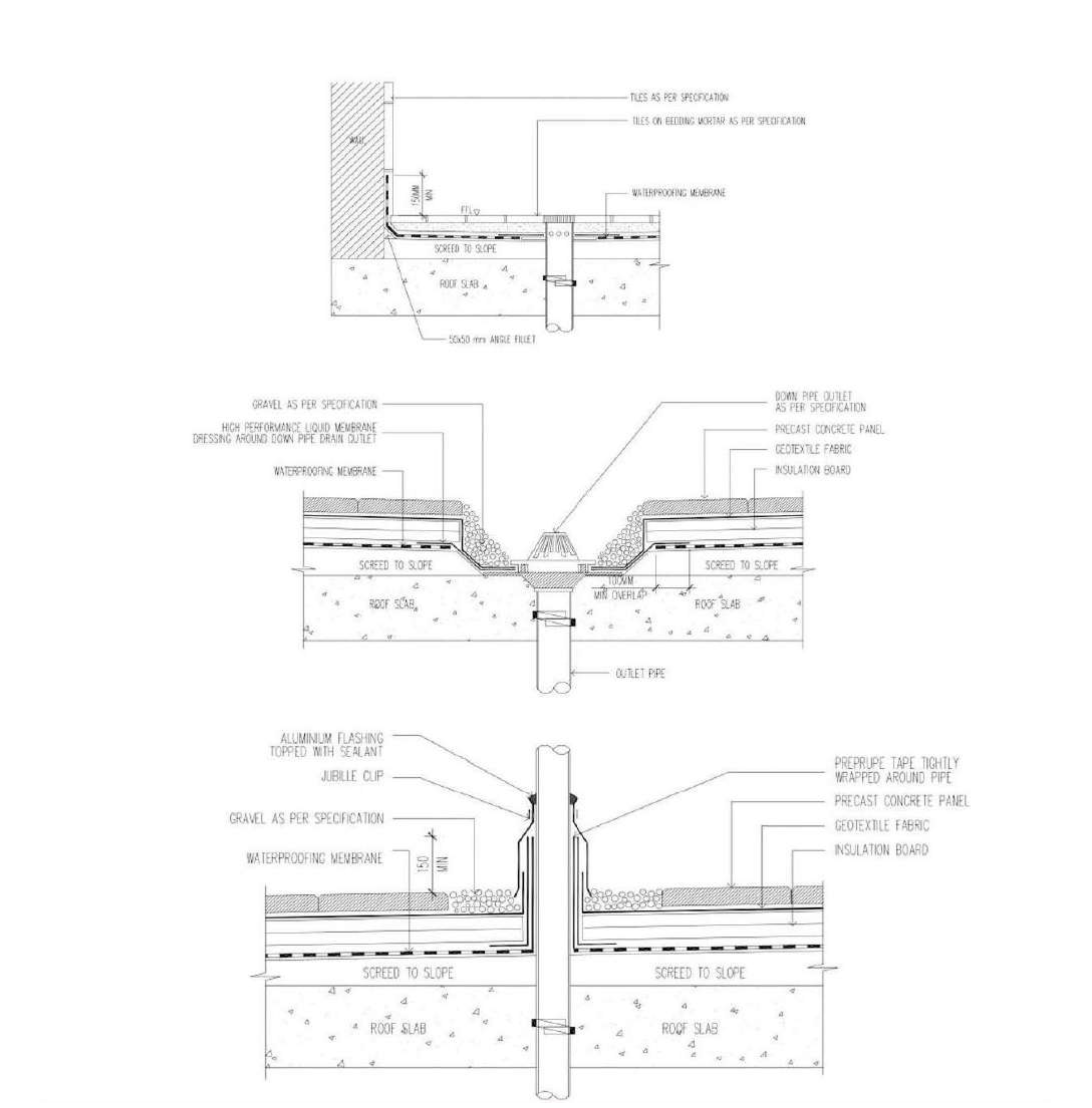

TECHNICAL DETAILS